| Home > Technique & Knowledge > Uniqueness of Japanese Planes |

But there are several aspects that are quite unique to Japanese planes.

1. They are used by a pulling motion.

| Most commonly used Japanese plane blade's width is usually wider than that of western plane, which means there is more weight when planing. Since Asian (especially Japanese) people are much smaller compared to western people, they needed to devise an easier way to plane the timbre. The answer was to pull. By pulling you are using the largest muscle in the upper body (the back muscle Latissimus Dorsi) and there is no need for your smaller shoulder muscles (deltoids) to exert to relay the strength generated by the large back muscle. | ||

2. The blade has laminated steel.

| There are multiple benefits from this design. The below are the major benefits for the users. (There are other set of benefits for the maker as well.) | ||||||||||||

|

||||||||||||

3. The back of the blade has a hollow.

|

||

This makes it much easier to keep the back flat, with only a portion of the surface touching the stone. It is very important to

have the back absolutely flat in order to produce a complete straight (almost complete) edge. I will explain more on sharpening section.

The less area touching the stone, the easier maintaining the flat. It is very important to keep this shape by using a flat stone, and knowing how to

make it flat in the beginning for it would be warped to the steel side a little, if you start grinding without any care the hollow would look like this.

Deformed back is considered to be a shame among the top Japanese carpenters, but it is quite difficult to keep the back hollow in a nice shape. I will explain how to keep the back in the sharpening section. |

||

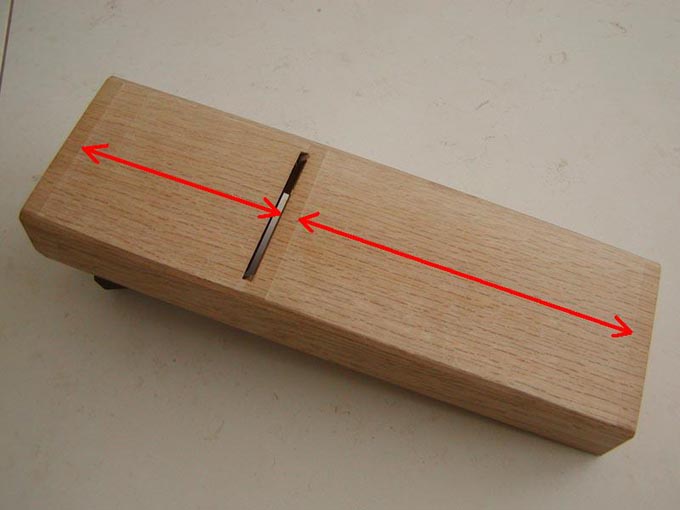

4. The block is wooden made.

| When the block is made of wood, you need to constantly keep adjusting the sole to be flat because there is a small movement according to the humidity change. Despite this major minus point, Japanese insist on using wooden block because there are a couple of major benefits that would more than compensate. First it would be significantly lighter in weight. Because Japanese style of construction heavily relied on planes, carpenters would use a plane all day long, sometimes day after day. And especially before the last WW, people didn't eat much meat so they were very small, so it meant a lot that their tools were lighter. There is another major merit. You can adjust the sole easier. Japanese plane's sole is not absolutely flat. There is a very slight concave shaved off by the user to reduce the friction. (Please refer to the picture in "How to use and adjust" section.) Without this concave, even the very best Japanese plane would never produce a micron thin shave. It is amazing how such a small difference would create a huge difference in performance. | ||

|

||

5. There are no dials and levers to adjust the blade setting.

| This could be a major minus point for entrant users, and major plus for skilled users. It is much more difficult to set the blade compared to western style planes. I was surprised how easy it was to set the blade for western planes. But once you get used to it, this means lighter tool. | ||

6. They are designed to polish the timbre without using any sandpaper.

| Japanese traditional style of wood working and construction does not use any sandpaper for finishing the timbre.

The mirror like finish is achieved by thinly (3 to 15 microns) shaving off the timbre with a razor sharp blade. You can actually see the view

reflecting onto the timbre. Above 2 and 3 contributes to achieve this unbelievable performance.

|

||